Dynalab NX Testers offer a wide array of solutions for the wire harness industry. A few of these solutions and their associated benefits are described below.

Label Printing

NX Testers can be programmed to print a label every time a wire harness passes all tests. This provides an excellent quality control mechanism to ensure that only good wire harnesses receive labels. Dynamic data can be printed such as a date stamp, operator ID, and part number along with static data such as company name and logo. Compatible label printers are available from Dynalab. Learn more

Barcode Scanning

NX Testers can accept input from a barcode scanner and automatically launch the desired test program either from local storage or from a central repository on the NX Server. Input from a barcode scanner can also be used to communicate data to be printed such as operator ID, lot number, product ID, etc. Learn more

Security

Every NX Tester is equipped with a port, accessible on the front panel. This port accepts a Supervisor Key which unlocks access to setup menus, permits program termination, and activates the control port. The Supervisor Key can be used to abort a test in progress and remove a defective harness from the fixture board.

Dynalab offers an optional security feature for the NX Editor and NX View software that requires user id and password verification to gain access to program editing privileges. This feature uses a single security file to validate user authorization for an entire facility or company. Learn more

Controlling External Devices

NX Testers are capable of interfacing to external devices by activating control output contacts. Additionally, NX Testers can be programmed to respond to inputs from external devices. To support these capabilities, Dynalab offers the Control Port Module (2 outputs / 1 input) or the Modular Control System (up to 64 outputs/inputs). Learn more

Data Reporting

NX Testers can report data for each wire harness. Data can include serial number, part number, operator ID, time and date, and many other attributes. The measured resistance value of each circuit can also be reported. Reports can be printed, sent to the NX Server, stored on the tester’s memory card, or saved to a spreadsheet or flat file. Learn more

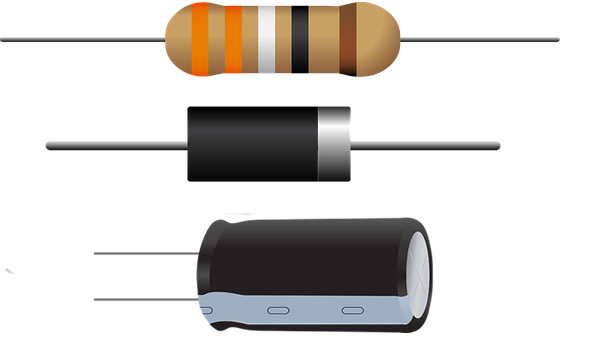

Component Testing

NX Testers can be programmed to test resistors, capacitors, diodes, and thermistors. A generic component test is also available to extend the flexibility of the NX Tester’s component testing capabilities.

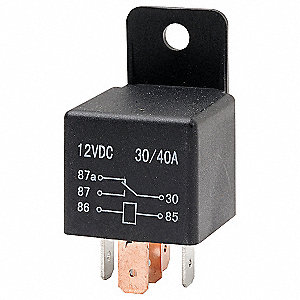

Active Relay Testing

Many automotive wire harnesses contain relays. NX Testers support active relay testing where each relay is energized to validate proper operation.

Hipot Testing

NX Hipot Testers are available in DC-only or AC/DC for testing dielectric withstand and insulation resistance. These testers also provide standard low voltage continuity and shorts testing to provide a complete testing solution.

Detecting Intermittent Connections

NX Testers can continuously test for intermittent opens and shorts while the operator flexes the wire harness. The duration of the test can be specified as a fixed time duration, number of test cycles, or until the operator terminates the test.

VIN-specific test program creation

VIN-specific wire harness manufacturing environments require a unique test program to be generated automatically for each harness based on the features and option codes included in the wire harness. Dynalab has a solution to support this scenario.

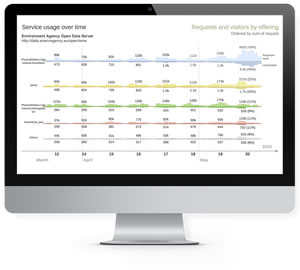

Centralized Control and Reporting

Dynalab’s NX Server allows you to control and monitor NX Testers and view report data from all NX Testers over a network through a simple yet powerful web-based interface. Learn more

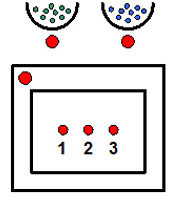

Guided Connector Pinning

Dynalab has a solution for assembling wires into connectors that use a push-click-pull wire insertion method. Dynalab’s solution guides the operator by indicating the desired parts bin from which to select the wire, illuminating an LED to highlight the target cavity on the connector, validating proper seating of the connector pin via a pull test, and testing continuity. Learn more

Computer-Tester Integration

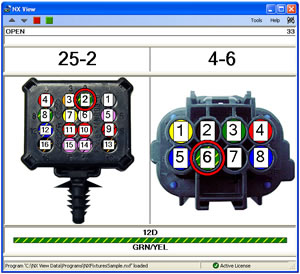

NX View software resides on a PC and seamlessly integrates with an NX Tester to provide a powerful graphical user interface which displays connector images showing the operator which connectors and cavities are associated with error conditions. NX View also displays all errors of the wire harness being tested in a single window. NX View can display an image of the fixture board, highlighting the fixture blocks associated with error conditions. Instructional information be displayed such as custom messages, production aid documents or videos – anything that can be displayed in a web browser can be displayed on NX View. This enables operators to be more effective in dealing with specific error conditions or assembly operations. NX View has built-in data collection and can store report data in a spreadsheet, PDF file, or text file. Learn more

Alarm Mode

The NX Tester can be programmed to enter an Alarm Mode whenever a wire harness has been removed from the fixture before testing has completed. The Alarm Mode aborts the test, sounds a continuous alarm, and displays a message indicating early removal of the wire harness. This behavior continues until an authorized person with a Supervisor Key disables the Alarm Mode. The Alarm Mode cannot be disabled in any other way. This provides an excellent method of ensuring that all wire harnesses are completely tested.

Illuminating Fixture LEDs

NX Testers are capable of illuminating fixture-mounted LEDs. Two modes are available: illuminate the fixtures that are associated with the currently displayed error or illuminate all fixtures that have unresolved connections.

Data Importation

The NX Editor is capable of importing relevant wire harness design information from a variety of external data sources to expedite test program development. Learn more