HV System

- 5000VAC / 6000VDC Hipot Testing

- 1MΩ – 9.5GΩ Insulation Resistance (IR)

- Stand-alone operation

- Supports network file transfer and reporting

- Accurate component testing

- Built for rough industrial environments

- Tests up to 256 high voltage test points

- Tests up to 384 standard voltage test points

The Dynalab HV System was specifically designed for the advanced EV (Electric Vehicle) wire harness testing requirements. This system builds on the solid capabilities of the Dynalab NX Hipot tester with the ability to perform a Hipot test up to 5000VAC and 6000VDC.

The powerful NX Editor software application is used to create unique program files to successfully validate all electrical and electro-mechanical wire harness parameters. This tester is compatible with all Dynalab NX accessories such as printers, scanners, control ports, and much more.

For test applications that span the range from simple to complex, Dynalab’s NX Testers offer more features than the competition at a lower price!

| Item | Specifications |

| Hipot Range | 100 VDC – 6,000 VDC (± 1%, +5V, no load) 100 VAC – 5,000 VAC (± 1%, +5V, no load) |

| Insulation Resistance Range | 1 MΩ – 9.5 GΩ (± 5%, +1MΩ) |

| Connections | Continuity: 0.1 Ω - 10 Ω (±0.1Ω) 10 Ω - 500KΩ (±1%) 500KΩ - 2MΩ (±5%) Shorts: 1KΩ - 2MΩ (± 20%) |

| Components | Resistors: 0.1 Ω -10 Ω (±0.1Ω) 10 Ω - 500KΩ (±1%) 500KΩ - 2MΩ (±5%) Diodes: Checks for proper orientation Capacitors: 100pF - 100,000uF (±2% to ±20%, ±60pF based on capacitor type) |

| 4-Wire (Kelvin) Mode | 0.005 Ω - 100 Ω (±1%, ±0.005 Ω) |

| Testing Method | Utilizes proprietary electronic switching circuits designed to validate connections from NX Editor program data. |

| Continuity Test Voltage | Test voltage is defined by the NX Tester for optimum resistance measurements. The voltage will not exceed 14VDC and cannot be configured by the user. |

| Continuity Test Current | Test current is defined by the NX Tester for optimum measurements. The current will not exceed 5mA DC and cannot be configured by the user. |

| Test Speed | 1 seconds per 1024 test points (continuity only) 3 seconds per 1024 test points (continuity and shorts) 1 second per connection group (Hipot-DW) 1 second per connection group (Hipot-IR) |

| Display | Errors are displayed using connector names, wire names, and wire color on a 4-line x 20 character display. |

| Audible Tones | Provides a variety of user programmable tones for error notification and special events. |

| Program Storage | Approximately 150 to 250 test programs containing under 256 test points. File storage will be reduced with programs that contain higher test point counts. 3.3MB Internal Memory Size. |

| Control Port | Connects the optional Control Port Module for controlling two outputs and monitoring one input. |

| Serial Ports | Two RS-232 serial ports for connecting printers, bar code scanners, extended displays or the Modular Control System. Two additional RS-232 ports are available with the optional Communication Board. |

| Network Port | Network port to allow communication to the NX Server for program file transfers and advanced reporting. Available with the optional Communication Board (100 Mbps). |

| Test Point Interface | High Voltage Banana Plugs |

| Input Power | Uses external power supply rated for 100 – 240VAC, 50-60Hz, 30W max. Power supply provides 15VDC to the NX Tester. |

| Test Point Capacity | 8 - 256 high voltage test points (8 test point increments) 128 - 384 standard voltage test points (128 test point increments) |

| Size (W x D x H) | NX Hipot HV+ Expansion Unit: 12” x 11.5” x 9” (33 cm x 28 cm x 25 cm) High Voltage Source: 13” x 17.8” x 5.8” (33 cm x 45 x 14.8 cm) NX Pro Tester: 10.7” x 7.5” x 4” (27.2cm x 19 cm x 9.7cm) |

| Weight | NX Hipot-HV Expansion Unit: 27 lbs (12.3 Kg) High Voltage Source: 32 lbs (14.5 Kg) NX Pro Tester: 6.6 lbs (3 Kg) |

| Operating Parameters | Temperature: 32– 122 degrees F (0– 50 degrees Celsius) Humidity: 75% non-condensing |

| Warranty | One year parts and labor |

| Certifications | CE Certified |

HV Interface (High Voltage)

The HV Lead consists of a high voltage plug with a 18 AWG wires, ready to be connected to a fixture board.

Part Numbers:

5-2301…..HV Lead, 6 feet (1.8 m)

5-2302…..HV Lead, 12 feet (3.6 m)

High Voltage Plug. Part Number: 5-8639

Terminal Block Interface (Standard Voltage)

The terminal block and ribbon cable are used to connect the customer’s test fixture to the NX Tester. Learn More

Discrete Wire Interface (Low Voltage)

The edge connector and discrete wires are used to connect the customer’s test fixture to the NX Tester. Learn More

HV Test Point Board

Each HV Test Point Board provides an additional 8 test points for any HV System. A lead to connect to the fixture block is included for each test point. Part Number: 5-4017

HV Expansion Unit

The HV Expansion Unit can contain up to four HV Test Point Boards and accommodate up to 32 test points. Part Number: 10-0XX (Change part number to specify test point quantity in 8 points increments; i.e., 10-016 contains 16 test points)

Test Point Board (Standard Voltage)

Each board adds 128 test points to any NX Tester that has available space. Part Number: 5-4002

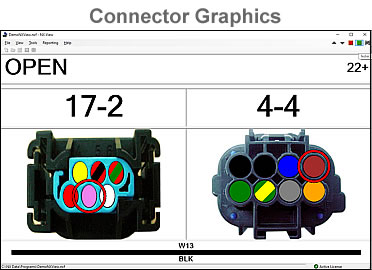

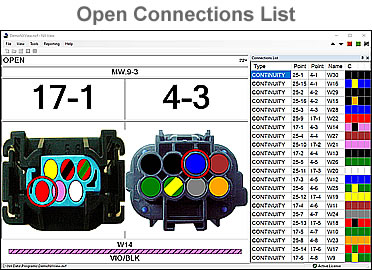

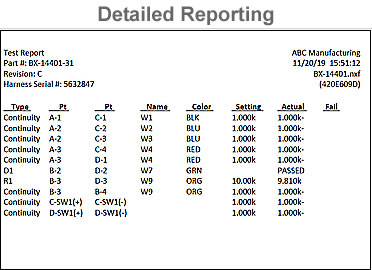

Enhance the NX Tester’s graphics and reporting capabilities with the NX View software application.

Select the part number below that corresponds to the quantity of test points required (How to calculate?)

| Part # | Description |

| 9-XXX-1 | HV Test System consists of a Dynalab NX Pro Tester w/128 standard voltage test points, HV Expansion Unit(s) and GW Instek High Voltage Source. XXX indicates the quantity of high voltage test points. Change part number to specify test point quantity in 8 points increments up to 32 test points(i.e., 9-032-1 contains 32 test points). For more than 32 test points, additional HV Expansion Units can be added. Use the part number 10-0XX (Change part number to specify test point quantity in 8 points increments; i.e., 10-016 contains 16 test points). Additional standard voltage test points are purchased separately with part number 5-4002. |

| NX View Software |

| Software application that enhances the user experience with additional information, graphics, program storage and reporting. Learn More |